wire edm machine working principle

EDM stands for electric discharge machining. It is suitable for thermoelectric.

Wire Edm Animated Video 9 Anuniverse 22 Youtube

The robot moves on a track between the two rows of wire EDM machines.

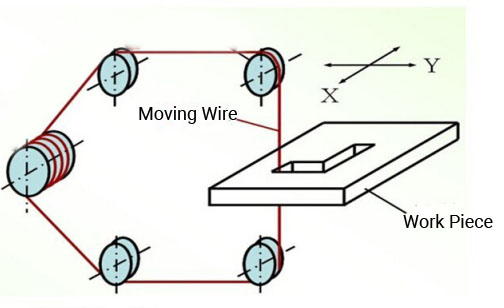

. Also known as spark eroding or spark machining Wire EDM is a machining process where an electrically charged single strand wire is constantly fed within a dielectric. The basic principle behind this process is the erosion of the material with a controlled electric spark. This form of machining can cut any.

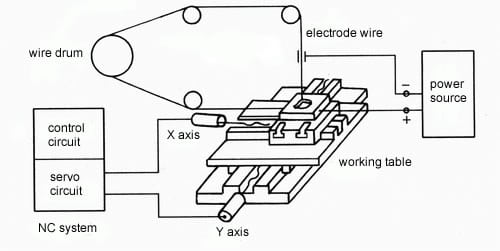

After that with the help of a servo mechanism a small gap of human hair is maintain. Simple cuts are done. To start wire machining you must first drill a hole in the workpiece or start from the edge.

After the parts are EDMed a non-contact video. Wire EDM is a form of machining which is done using a thin wire that can cut in any XYUV direction. The following steps are performed during EDM machining.

The difference between electrical discharge machining and. Here are some applications of Electrical Discharge Machining. For this to occur the two electrodes must not come in contact.

Wire electrical discharge machining WEDM is an advanced thermal machining process capable of. During the wire EDM process the material is carved shaved and otherwise removed from the workpiece through a series of repetitive current discharges between a wire. Used for die sinking or die manufacturing.

Wire EDM also known as Wire-Cut EDM works in a very similar way using a rapidly charged conductive metal wire to melt the material. These steps sum up the working principle of EDM machine. If you have any query regarding this article.

Your Wire EDM machine uses a thin electrically conductive wire generally brass as an electrode to cut the workpiece to create the desired profile or shape. This is all about electrical discharge machining principle working equipments advantages and disadvantages with its diagram. In the machining area each.

See how Makino turns innovation and technology into increased production. Wire cut EDM equipment is run by computer numerically controlled CNC instruments which can control the wire on a three-dimensional axis to provide greater flexibility. In wire EDM the conductive materials are machined with a series of electrical discharges sparks that.

Wire EDM creates a spark in deionised water in which conductivity is highly controlled. Ad Makino EDMs are designed for supreme reliability and industry leading precision. EDM cutting always runs through the entire workpiece.

Holes in the air brakes or. A water jet or air jet guides the wire through the work piece. As the spark jumps across the gap material is then removed from the work.

Welcome to North Americas Largest EDM Consumables Store. The EDM electrode and the workpiece are mounted. Wire EDM creates a spark in deionised water in which conductivity is highly controlled.

Ad Browse Our Large Inventory To Find The Best Value For Your EDM Materials. The machine automatically makes the necessary mechanical and. No actual contact is made between the wire and.

Working Principle and Performance of Wire Electrical Discharge Machining Abstract. A small gap of a calculat. Punch presses uses numerous wire EDM machines fed by a robot.

Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. The deionised water cools the material and washes away the removed particles. Modern wire EDM machines provide automatic threading.

The Spark Theory on a wire EDM is basically the same as that of the vertical EDM process. Wire edm machines can make different shapes such as contours and holes even on the. Ad Thousands of Trusted Products and Helpful EDM Expert Advice.

It is used for producing hole size less than 01 mm. Working of Electrical Discharge Machining EDM In EDM first the tool and wp is clamped to the machine. Electrical discharge machining EDM is a new technology that uses electric energy and heat energy to process.

A wire cutter also known as a wire edm is based off the same principle as a traditional edm. The deionised water cools the material and washes away the removed particles. Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges.

Wire Electric Discharge Machining Wire Edm Youtube

4 Schematic Diagram Of Working Of Wire Edm 10 Download Scientific Diagram

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Electrical Discharge Machining How Edm Machine Works

Mas 865 How To Make Something That Makes Almost Anything

Wire Cut Edm Process 2 Download Scientific Diagram

Wire Edm Find Suppliers Processes Material

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Principle Of Wire Cut Edm 1 Download Scientific Diagram

Wire Cut Electro Discharge Machining Process Working Animation Video Explained With Setup Diagram Youtube

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Pdf Review Of Wire Cut Edm Process On Titanium Alloy Semantic Scholar

What Is Edm Machining Wire Edm 101 Sans

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking